Types of PEB Frames and Their Applications in Modern Construction

Pre-Engineered Buildings (PEBs) have brought about a significant transformation in the construction sector by providing efficient, economical, and durable building solutions. These structures are prefabricated in factories and assembled on-site, drastically reducing construction time, minimizing labor, and ensuring high quality. One of the most critical elements of any PEB is its frame. The frame determines the structural integrity, usability, and cost-effectiveness of the building. Selecting the appropriate frame type is essential for ensuring the building meets the intended functional and architectural requirements.

In this blog, we will delve deep into the various types of PEB frames, their structural features, advantages, and the types of projects they are best suited for.

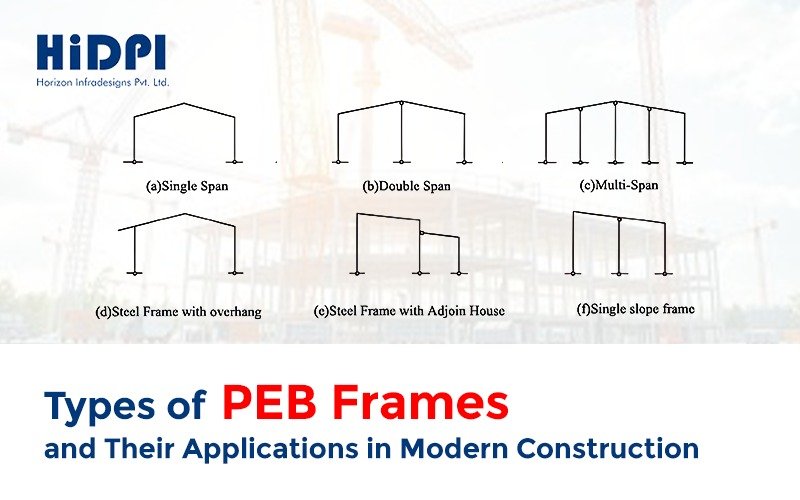

Types of PEB frames

1. Clear Span Frame

Definition: A clear span frame is a type of structural framing system that spans across a large width without the need for any internal supporting columns. This design is achieved by transferring the entire load of the roof and walls directly to the end columns, usually located at the building’s sides. As a result, the internal area remains entirely free from obstructions, offering maximum usable space. These frames are typically constructed using rigid steel members engineered to withstand high loads while maintaining a sleek and open appearance. Clear span frames are especially beneficial for applications where uninterrupted interior space is essential for operations, movement, or layout flexibility.

Applications:

- Aircraft hangars

- Exhibition halls

- Warehouses

- Indoor sports complexes

Advantages:

- Provides maximum usable floor space without any obstructions

- Ideal for applications requiring open floor plans

- Offers great flexibility for interior layouts and equipment installation

- Enhances aesthetics with a clean and open structure

Clear span frames are particularly beneficial in buildings where movement and storage of large equipment or goods are necessary. The lack of interior columns facilitates free movement, making these frames a popular choice for aviation, logistics, and warehousing industries.

2. Multi Span Frames

Definition: Multi-span frames are a type of structural system that incorporates one or more interior columns along the width of the building to help distribute the roof and structural loads more efficiently. By integrating internal columns, these frames allow for broader buildings without requiring oversized or over-engineered beams and rafters, which helps reduce construction costs. The design provides increased stability and strength, making it suitable for large-scale industrial or commercial buildings where some internal supports do not interfere with operations. Multi-span frames are versatile and can be customized with different spacing configurations, depending on the project requirements.

Sub-Types:

MS1 (Multi-Span Type 1):

- Features evenly spaced interior columns

- Offers a symmetrical and balanced design

- Suitable for standard industrial buildings and large commercial spaces

MS2 (Multi-Span Type 2):

- Features irregular spacing of columns

- Designed for buildings with unique layout or usage requirements

- Ideal for facilities with specific equipment or space zoning needs

MS3 (Multi-Span Type 3):

- Combines both regular and irregular spacing

- Offers flexibility in design and layout customization

- Best for complex industrial units or projects requiring adaptive space planning

Applications:

- Manufacturing plants

- Warehousing and distribution centers

- Industrial production units

Advantages:

- Cost-effective for larger span buildings

- Enhanced structural support for heavy roof and equipment loads

- Flexible design for integrating mezzanines, cranes, and utilities

- Easier to expand or modify as operational needs grow

Multi-span frames are often used where open floor space is not a strict requirement, and interior columns can be strategically placed without disrupting operations. They offer a practical balance between structural efficiency and material cost.

3. Single Slope Frame

Definition: A single slope frame features one roof surface sloping in one direction. Unlike the symmetrical double-slope frames, this design has one side of the building higher than the other, creating a natural slope ideal for water drainage and solar panel installations. It’s simple, effective, and often used in buildings that require aesthetic or functional asymmetry.

Applications:

- Retail outlets

- Office spaces

- Garages and workshops

- Extension of existing buildings

Advantages:

- Facilitates water drainage naturally

- Easier to install solar panels on sloped roof

- Cost-effective for small to medium-sized buildings

- Useful for attaching lean-to or annex structures

Single slope frames are a great choice for buildings where drainage is a priority or for design elements requiring a modern or minimalistic look. They are also commonly used in areas where zoning laws require specific height or drainage provisions.

4. Multi Gable Frame

Definition: Multi gable frames consist of multiple ridges or gables across the structure. This creates a visually segmented roof profile while maintaining structural strength. It allows large spaces to be divided into zones while still being housed under one continuous structure.

Applications:

- Educational institutions

- Commercial buildings

- Government complexes

- Public facilities

Advantages:

- Aesthetic appeal with segmented design

- Helps divide large buildings into functional zones

- Supports more complex roofing and ventilation systems

Multi gable frames are ideal for buildings that cater to a variety of uses under one roof. Their segmented form provides both visual structure and functional organization.

5. Lean-To Frame

Definition: A lean-to frame is an extension frame that is attached to an existing structure. It has a single slope roof and usually acts as an annex to the main building. Lean-to frames are economical and suitable for temporary or auxiliary purposes.

Applications:

- Storage sheds

- Utility spaces

- Covered parking

- Loading docks

Advantages:

- Quick and low-cost construction

- Ideal for expanding existing buildings

- Great for temporary or support functions

Lean-to frames provide a simple solution when extra space is needed adjacent to a main structure. They are quick to install and highly economical.

6. Crane-Lift Frame

Definition: Crane-lift frames are specially designed to support the loads of overhead cranes used inside industrial buildings. These frames require precise engineering to handle dynamic and vertical loads.

Applications:

- Heavy industrial facilities

- Fabrication units

- Automobile manufacturing plants

- Foundries and workshops

Advantages:

- Designed to integrate with EOT cranes

- Handles high vertical and lateral loads

- Increases operational efficiency

Crane-lift frames are a necessity in manufacturing environments where heavy lifting equipment is a daily part of operations.

7. Hybrid Frame

Definition: Hybrid frames combine two or more different framing systems to meet specific architectural or operational requirements. These designs are tailored to complex projects that require unique solutions.

Applications:

- Mixed-use buildings

- Industrial-cum-commercial complexes

- Buildings with large mezzanines or multi-levels

Advantages:

- Combines strengths of multiple frame types

- Offers tailored solutions for unique projects

- Enables creative and functional flexibility

Hybrid frames are often the go-to choice for architects working on innovative or multi-use buildings.

8. Green PEBs

Definition: Green PEBs focus on sustainability and energy efficiency. These buildings incorporate eco-friendly materials, insulation, natural ventilation, rainwater harvesting systems, and solar panels into the design and frame selection.

Applications:

- Green factories and offices

- Educational institutions

- Warehouses with sustainability goals

Advantages:

- Reduces energy consumption

- Supports green building certifications (LEED, GRIHA)

- Environmentally responsible and future-ready

Green PEBs are the future of sustainable construction and reflect growing awareness of climate change and energy conservation.

Consult Horizon InfraDesigns for PEB Construction

When it comes to implementing the right PEB frame for your industrial or commercial project, expert consultation and execution are key. Horizon InfraDesigns, based in Jaipur, is one of the leading names in the design and construction of PEB Building Manufacturers in Rajasthan.

With years of experience and a strong portfolio of successful industrial and infrastructure projects, Horizon InfraDesigns offers tailored PEB solutions, including clear span, multi-span, crane-supported, and hybrid frames. Our team ensures optimal structural design, precision manufacturing, and timely execution — making us a trusted construction company in Jaipur for industrial construction.

Whether you're planning a warehouse, factory, hospital, or a commercial space, we combines engineering excellence with modern construction techniques to deliver high-quality, cost-effective PEB structures.

Conclusion

Choosing the right PEB frame is essential to the success of your construction project. Each frame type serves specific needs, from the wide-open spaces of clear span frames to the load-handling capacity of crane-lift systems and the eco-friendly features of green PEBs. Understanding these options helps you build smarter, faster, and more efficiently.

Horizon InfraDesigns stands out as a reliable Structural Engineering Consultants, offering comprehensive PEB solutions that align with your operational goals and budget. Their expertise ensures not just a strong structure, but also long-term value and performance.